Working Principle of Spring-Loaded Safety Valves

Safety Valves

A Safety Valve (also known as a pressure relief valve) opens and closes automatically according to the operating pressure of a pressure system. It is generally installed on equipment or pipelines in closed systems to protect the system safety. When the pressure or temperature in the equipment or pipeline exceeds the set pressure of the safety valve, it automatically opens to relieve pressure or reduce temperature, ensuring that the medium pressure in the equipment and pipeline stays below the set pressure. This protects the normal operation of the equipment and pipeline, prevents accidents, and reduces losses.

Spring-Loaded Safety Valve

A spring-loaded safety valve is the most commonly used overpressure protection device in industrial fluid systems. Its core function is to automatically open and relieve pressure when the system pressure exceeds a set value; after the pressure returns to normal, it automatically closes by the spring force to prevent continuous leakage of the medium.

Working Principle

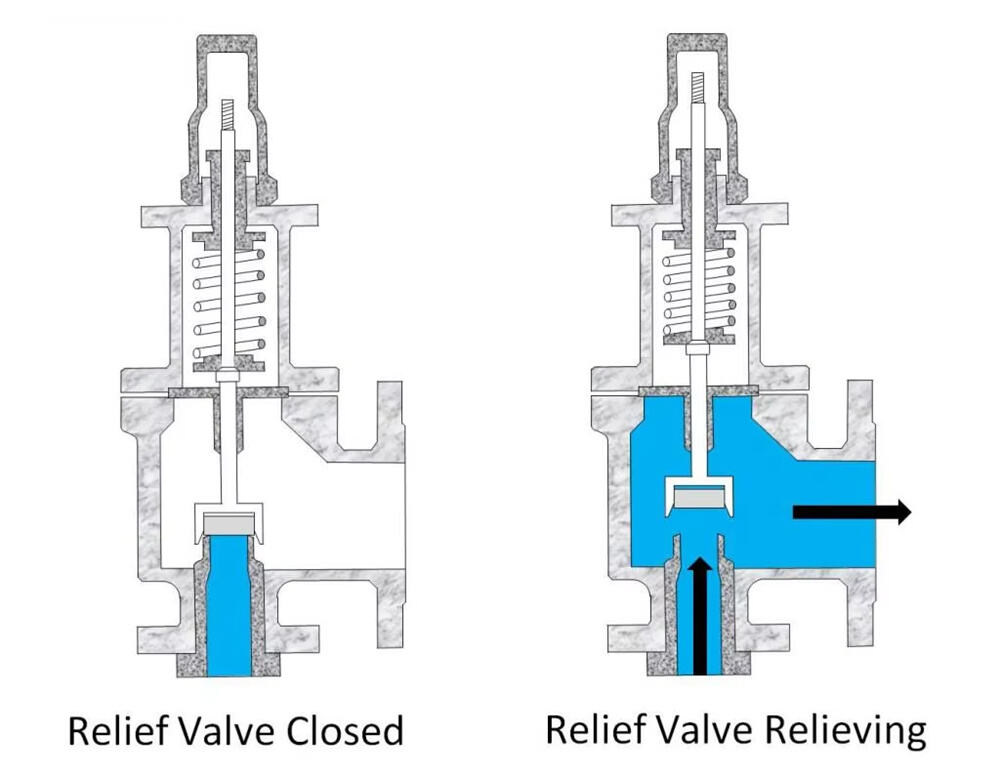

Closed State: During normal operation, the elastic force generated by the spring presses the valve core (valve disc) against the valve seat to form a seal. At this time, the force of the medium pressure acting on the valve core is less than the spring force, so the valve remains closed to prevent medium leakage.

Open State: When the system pressure rises above the pressure value set by the spring (set pressure), the upward force of the medium on the valve core is greater than the spring force. The valve core is lifted, the valve opens, and the medium is discharged through the gap between the valve seat and the valve core to release pressure.

Re-closed State: As the medium is discharged, the system pressure drops. When the pressure drops to a certain value below the set pressure (reseating pressure), the spring force becomes greater than the medium force again. The valve core falls back, reseals the valve seat, the valve closes, and the system returns to a stable state.

Structure of Spring-Loaded Safety Valves

The spring-loaded safety valve has a simple and mature structure, with few core components and a low failure rate, which is the core reason for its widespread use:

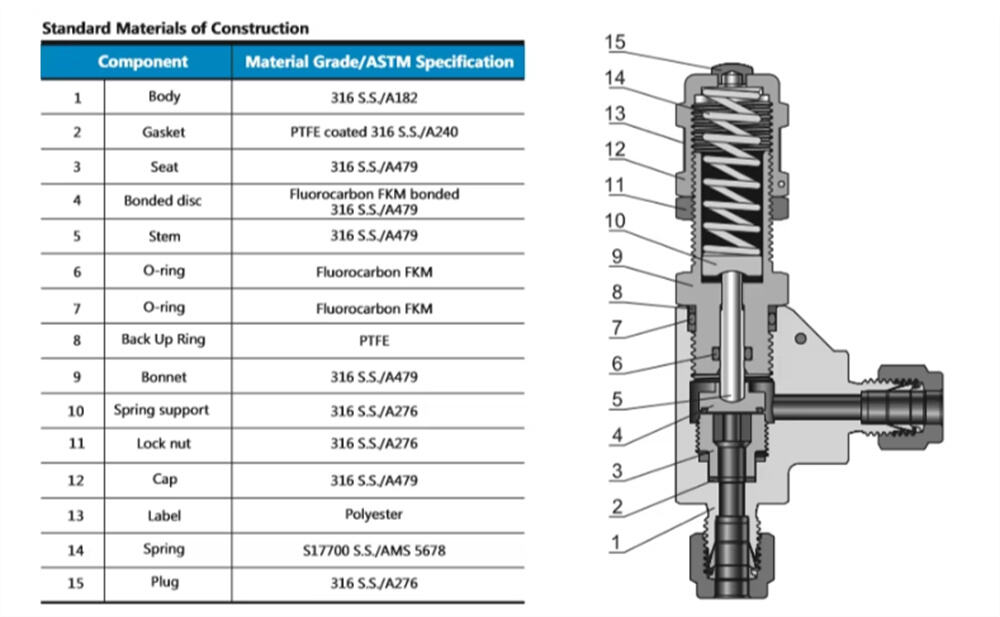

Valve Disc: It is a sealing component that blocks the valve seat. When the medium pressure does not exceed the limit, it is pressed against the valve seat by the spring force to maintain the seal.

Spring: It is the core driving component, which is divided into "direct spring-loaded type", "spring with guide sleeve type", etc. The set pressure is adjusted by changing the compression amount of the spring.

Valve Seat + Discharge Port: The valve seat cooperates with the valve disc to achieve sealing. The discharge port is used to discharge the overpressure medium (usually connected to a discharge pipeline to prevent the medium from leaking directly to the site).

EN

EN

AR

AR

HR

HR

CS

CS

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ