How does an electric contact pressure gauge differ from a regular pressure gauge in terms of cost?

How does an electric contact pressure gauge differ from a regular pressure gauge in terms of cost? Should I choose it or not?

In the field of instrumentation measurement, standard pressure gauges are simple in structure, economical and reliable, and widely used. However, when process control or alarms need to be based on pressure values, electric contact pressure gauges become necessary. Why does adding the "electric contact" function significantly increase the price? This article analyzes the price difference from four perspectives.

1 Structural Composition

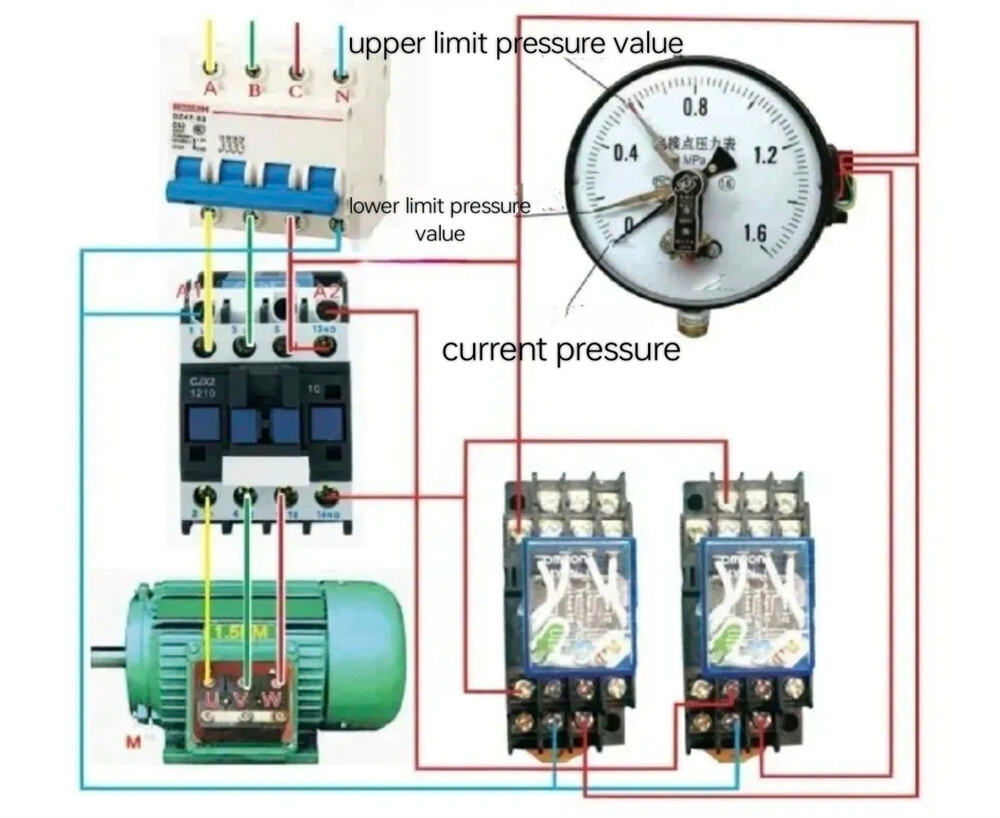

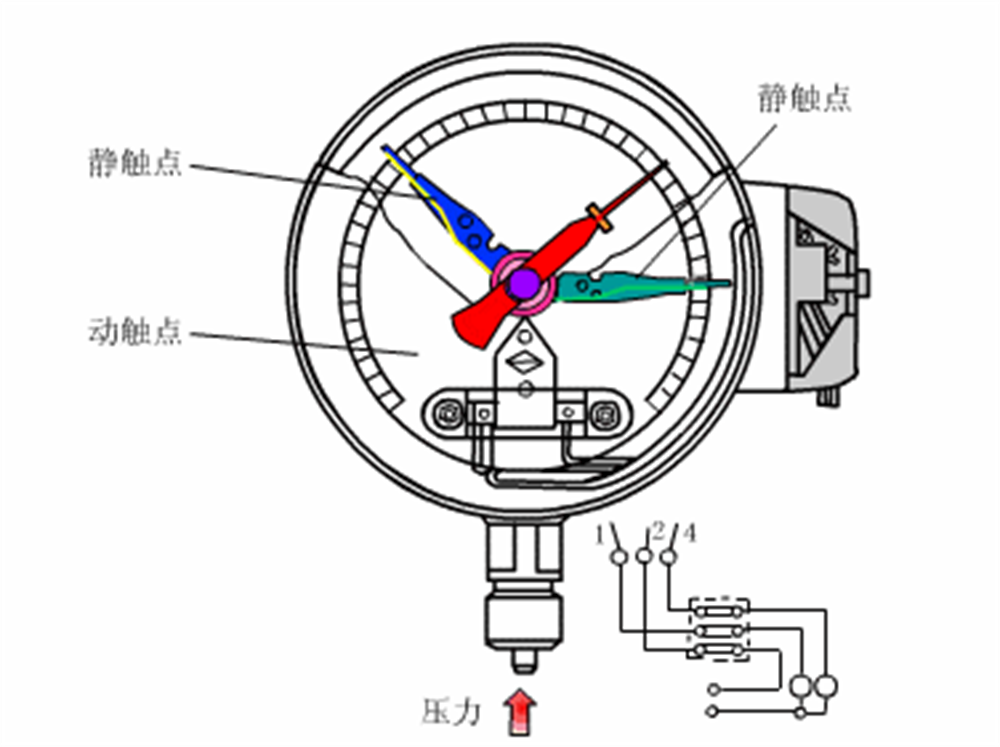

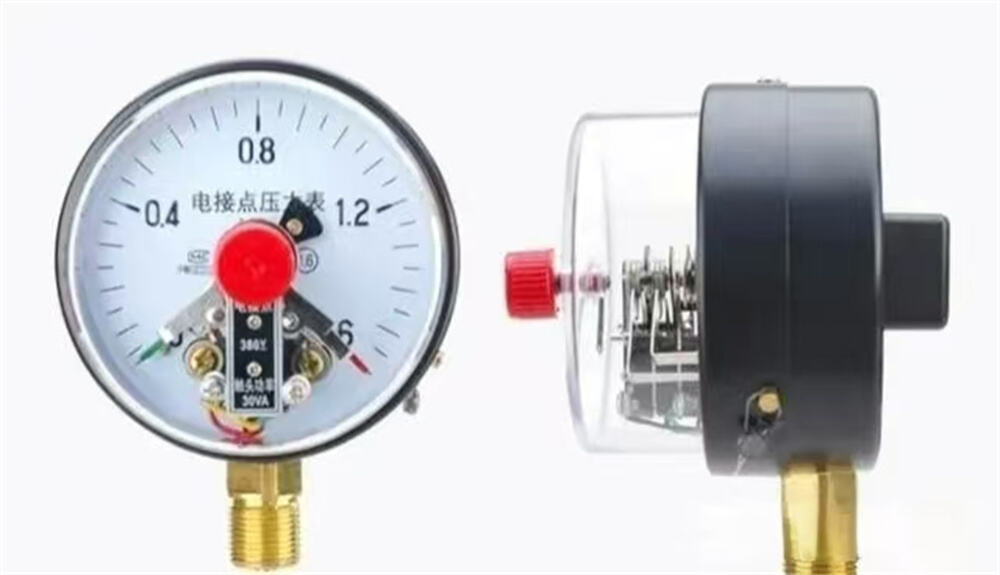

Electrical Contact Pressure Gauge: It consists of measuring system, indicating system, magnetic electric contact device, housing, adjustment device and junction box (plug socket) The Comfy Basics pressure gauge adds an electric contact device, including an electric contact signal needle and adjustable permanent magnet.

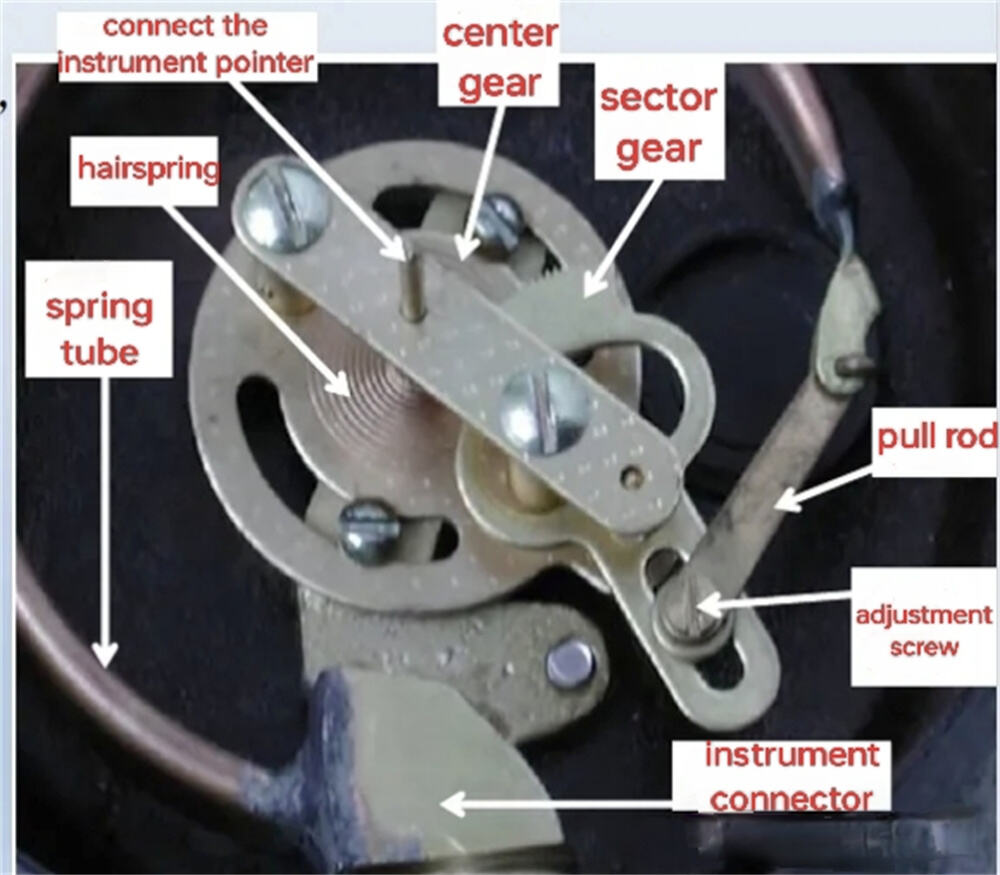

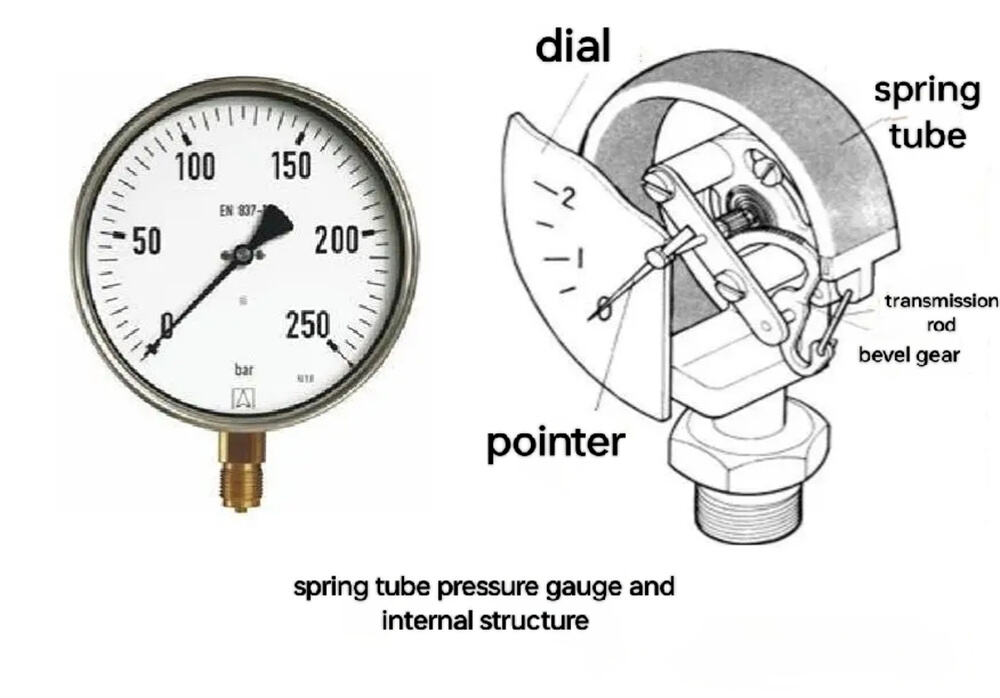

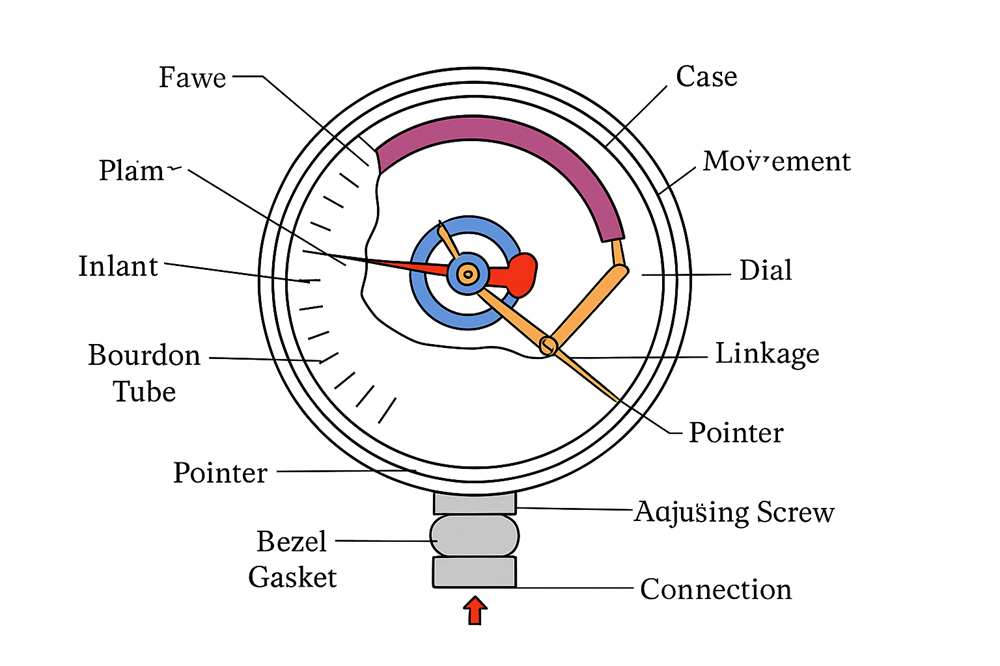

Ordinary Pressure Gauge: Generally consists of parts such as case, spring tube, fixed end, pull rod, fan gear, small gear, hands, hairspring, and tube connector.

2 Working Principle

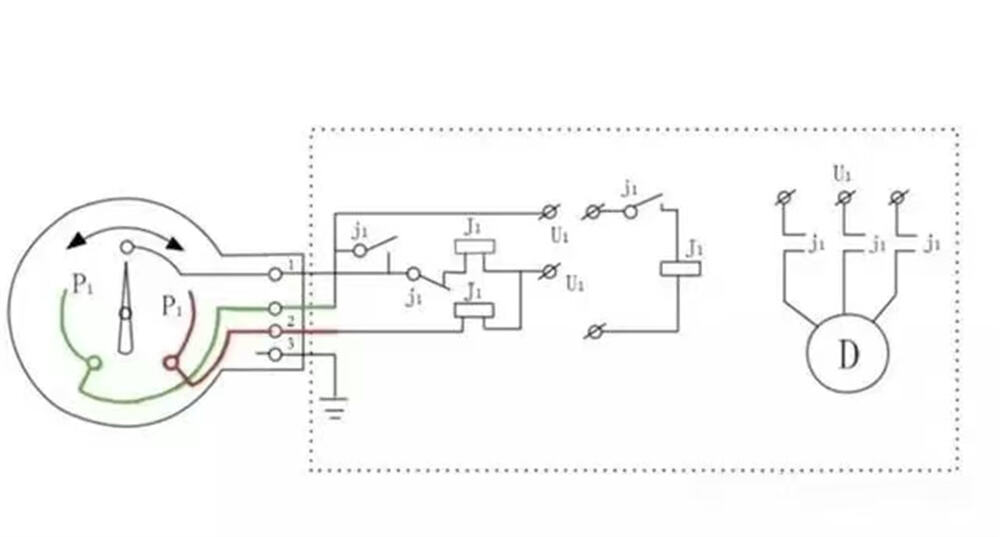

Electrical Contact Pressure Gauge: Based on the spring tube, when subjected to the pressure of the medium being measured, it undergoes elastic deformation and displacement. Through the pull rod and gear transmission mechanism, it is amplified and indicated on the dial by the fixed gear (along with the contact).

When the indicator needle contacts the contact point on the setting needle (upper or lower limit), the control system circuit disconnects or connects, achieving automatic control and alarm signaling purposes.

Ordinary Pressure Gauge: Through the elastic deformation of the sensitive element such as the Bourdon tube within the meter, the Bourdon tube's elastic deformation is converted into rotational motion by the meter's internal mechanism, causing the pointer to deflect to display pressure.

3 Functional Use

Electrical Contact Pressure Gauge: It can realize automatic control and alarm functions and is widely used in petroleum, chemical industry, metallurgy, electricity, machinery and other industrial sectors or as a component for mechanical and electrical equipment to automatically control and signal alarms for the monitored pressure system.

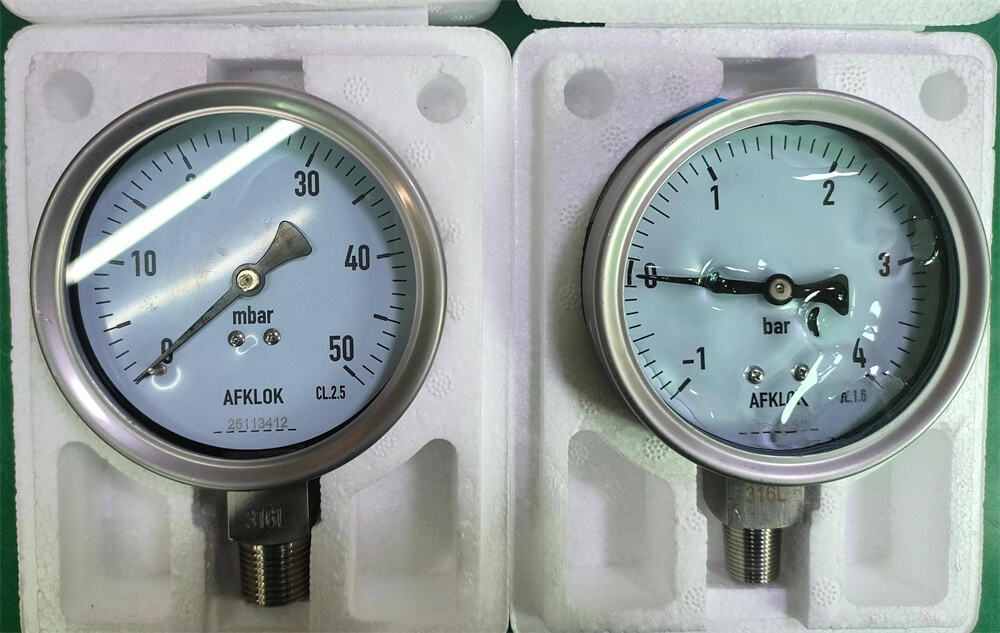

Ordinary Pressure Gauge: Mainly used to indicate pressure locally, suitable for measuring pressure and vacuum of liquids, gases, or vapors that are non-explosive, non-crystallizing, non-solidifying, and non-corrosive to copper and copper alloys.

4 Accuracy and Reliability

Electrical Contact Pressure Gauge: General accuracy levels can reach up to Class 1.6, and some high-precision models can meet more accurate measurements. Due to the use of electrical signal transmission and mechanical contact structure, it has high reliability and is relatively immune to environmental factors.

Ordinary Pressure Gauge: Accuracy levels include 1.0 class, 1.6 class, 2.5 class, 4.0 class, etc. Under normal usage conditions, they can meet general measurement requirements, but are greatly affected by environmental factors such as vibration and temperature.

5 Price Cost

Electrical Contact Pressure Gauge: Due to its electrical control function and more complex structure, the price is relatively high.

Ordinary Pressure Gauge: The structure is simple, the production process is mature, and the price is relatively low.

6 Selection Suggestions - Determine Based on Application Scenarios

Electrical Contact Pressure Gauge: Automatic equipment control: such as air compressor start and stop (stops at upper limit, starts at lower limit), water pump control, boiler safety valve control.

Limit Exceeding Alarm: Pressure vessel and lubrication system pressure abnormality triggers audible and visual alarms.

Simple interlock: prohibit starting the equipment when pressure is insufficient, and shut off the valve when pressure exceeds.

Independent security loop: As a hard-wired backup protection when PLC/DCS fails, it directly triggers security devices (such as emergency shut-off valves) to meet functional security (SIL) requirements.

Ordinary Pressure Gauge: Only manual observation of pressure values is required on site.

The pressure value is for record reference only and does not require any linkage with equipment.

Budget is limited and control/alarm functions are fully implemented by upper system (such as PLC/DCS) (except for key safety loop).

EN

EN

AR

AR

HR

HR

CS

CS

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ