Working Principle and Installation Precautions of Bimetallic Thermometers

Working Principle

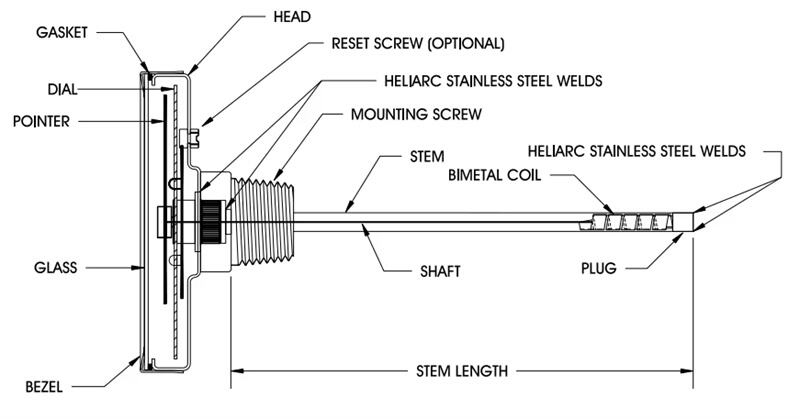

The working principle of a bimetallic thermometer is based on two metals with different thermal expansion coefficients. To improve temperature measurement sensitivity, the metal sheets are usually made into a spiral coil shape. When the temperature of the multi-layer metal sheets changes, each layer of metal expands or contracts to different degrees, causing the spiral coil to wind up or unwind.

Since one end of the spiral coil is fixed and the other end is connected to a freely rotatable pointer, when the bimetallic strip senses a temperature change, the pointer can indicate the temperature on a circular graduated scale.

The temperature measurement range of this type of instrument is generally between -80℃ and +500℃, with an allowable error of approximately 1.5% of the scale range.

Classification

Ordinary bimetallic thermometers, vibration-resistant bimetallic thermometers, and electric contact bimetallic thermometers.

According to the connection direction between the pointer dial and the protective tube of the bimetallic thermometer, it can be divided into four types: axial type, radial type, 135° angle type, and universal type.

①Axial bimetallic thermometer: The pointer dial is vertically connected to the protective tube.

② Radial bimetallic thermometer: The pointer dial is parallelly connected to the protective tube.

③ 135° angle bimetallic thermometer: The pointer dial is connected to the protective tube at a 135° angle.

④ Universal bimetallic thermometer: The connection angle between the pointer dial and the protective tube can be adjusted arbitrarily.

Selection and Usage

When selecting a bimetallic thermometer, full consideration should be given to the actual application environment and requirements, such as dial diameter, accuracy class, installation and fixing method, type of measured medium, and environmental hazards. In addition, factors such as cost-performance ratio and maintenance workload should also be taken into account.

Furthermore, the following points should be noted during the use of bimetallic thermometers:

A. The length of the protective tube of the bimetallic thermometer immersed in the measured medium must be greater than the length of the temperature-sensing element. Generally, the immersion length is greater than 100mm, and the immersion length for the 0-50℃ range is greater than 150mm to ensure measurement accuracy.

B. Various types of bimetallic thermometers are not suitable for measuring the temperature of media in open containers, and electric contact thermometers should not be used in control circuits in occasions with large operational vibrations.

C. During storage, use, installation, and transportation of the bimetallic thermometer, collision with the protective tube should be avoided. Do not bend or deform the protective tube, and do not use the thermometer as a wrench.

D. The thermometer should be regularly inspected under normal use conditions, generally every six months. Electric contact thermometers are not allowed to work under strong vibrations to avoid affecting the reliability of the contacts.

E. The temperature at which the instrument works regularly should preferably be within 1/3 to 2/3 of the scale range.

EN

EN

AR

AR

HR

HR

CS

CS

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ