High Purity Gas Selection Recommendation Solution

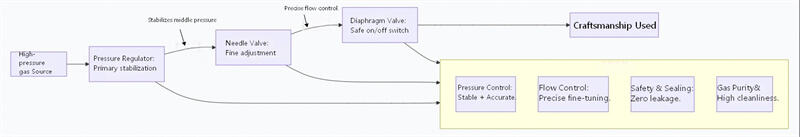

Configuration:R1D Series Pressure Regulator+Needle Valve+Diaphragm Valve+Check Valves.

Characteristics

This configuration offers the highest safety, the most precise control, and maximizes the protection of gas purity. Correspondingly, it comes with higher costs and potentially increased flow resistance.

Function

1. Pressure Regulator

It reduces the high pressure from the cylinder (e.g., 15 MPa) to a stable and safe intermediate pressure range in one step, providing a stable pressure starting point for precise downstream control.

2.Needle Valve

It actuates a needle-shaped plunger via a precision thread to achieve continuous, linear, and fine adjustment of gas flow. Its core function is precision.

3.Diaphragm Valve

It uses a flexible diaphragm to completely shut off or open the flow path. When closed, the diaphragm provides a complete seal to the flow channel, theoretically achieving zero leakage. Its core function is absolute sealing.

4.Check Valve ( Non-Return Valve)

It permits gas to flow in only one direction and automatically prevents reverse flow. In this advanced configuration, its core task is to prevent process media from flowing back and contaminating the gas source.

Key Usage Points and Selection Recommendations

1. Material Compatibility is Paramount

For corrosive gases (e.g., HCl, Cl₂), all components (valve body, diaphragm, seals) must be made of special alloys (such as Hastelloy or Monel) or high-grade stainless steel (e.g., 316L), and undergo strict surface passivation treatment.

2. Connection Type Matching

Such systems typically use metal face-seal fittings, such as VCR or double ferrule compression fittings, rather than traditional threaded seals, to ensure ultra-high purity and zero leakage.

3. Correct Installation Sequence

The standard order from the cylinder to the point of use is: Cylinder → Cylinder Valve → Pressure Regulator → Needle Valve → Diaphragm Valve → Piping → Reaction Equipment. The diaphragm valve serves as the shut-off valve closest to the point of use.

EN

EN

AR

AR

HR

HR

CS

CS

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ