Installation and Operation Manual for Model 2000 Cast Aluminum

Differential Pressure Gauge

Product Applications:

Widely used for measuring positive and negative pressure differentials in clean rooms or clean workshops of pharmaceutical factories and electronics factories; used in HVAC systems, clean air conditioning systems, and cleanroom air showers to measure pressure differentials across air filters; and as a matching component for pharmaceutical machinery and equipment.

Product Features:

• Fully precision-cast aluminum housing.

• Magnetic spiral worm mechanism eliminates friction caused by gear transmission.

• No liquid filling required inside the gauge.

• Pointer movement with no inertia, no drift, and essentially no hysteresis.

• Excellent vibration and jitter resistance.

• Superior overpressure resistance, capable of measuring positive pressure, negative pressure, or differential pressure.

• Flexible installation options.

Specifications:

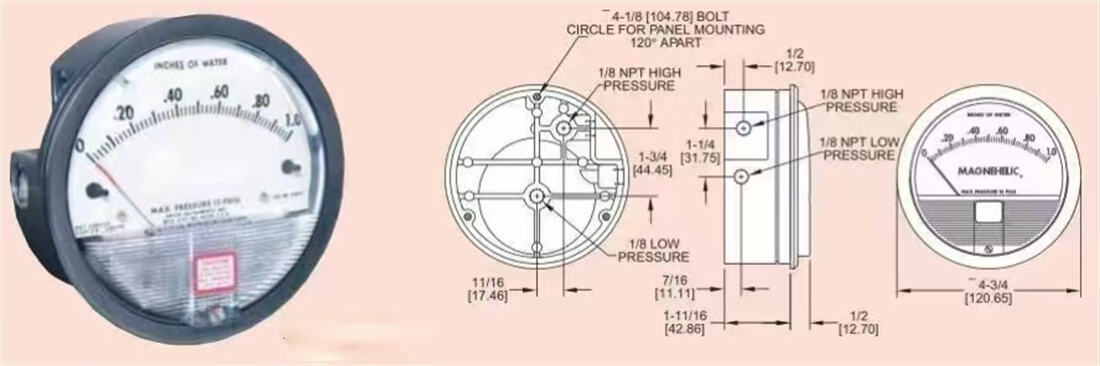

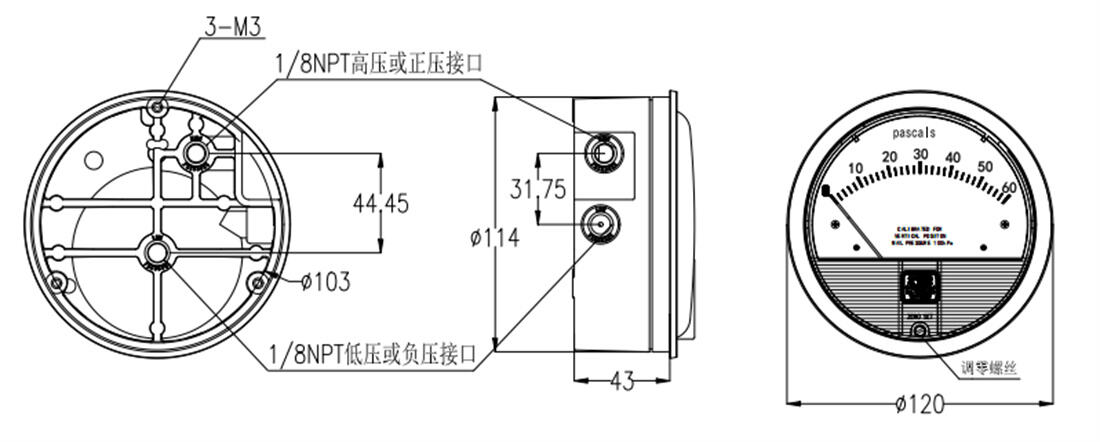

• Dimensions: 120*55.6mm

• Weight: Approximately 560 grams

• Surface Treatment: Powder coating

• Connections: 1/8NPT female thread dual high/low pressure ports (rear)

• Measurement Range: Min 30Pa, Max 5kPa

• Accuracy (at 21'): +2% F.S. (+3% for 125Pa and 250Pa models; +4% for 60Pa model)

• Temperature Range: -7'℃ to 60°C

Accessory List:

1. Two brass barbed hose fittings

2. Two 1/8NPT male pipe plugs

3.Three flush-mounting screw bases and screws

Note:

This product is only suitable for air or other non-corrosive gases!

Fixed Installation:

1. Select a location free of severe vibration with an ambient temperature not exceeding 60'C (140°F). Avoid direct sunlight to prevent accelerated aging of the plastic cover, Excessively long air hoses will extend response time; ensure no kinking of hoses. lf pointer oscillation is excessive due to pulsating pressure or vibration, contact the manufacturer to obtain a throttling damping device.

2. This differential pressure gauge is factory- calibrated for vertical installation as standard. lf non-vertical installation is required, please specify this in the order.

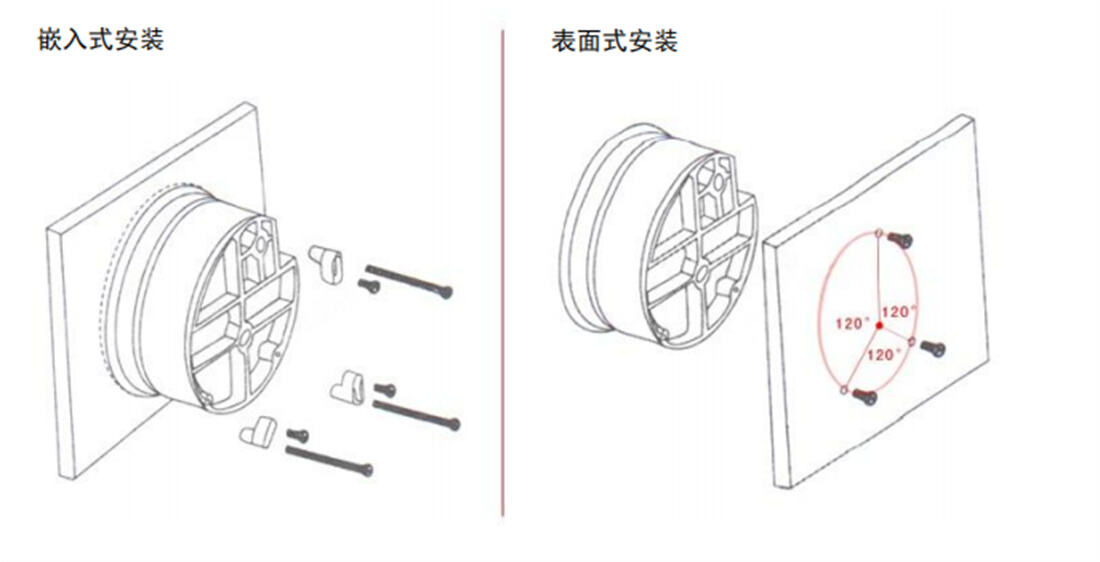

3. Surface mounting features three screw holes spaced at 120° intervals.

4. For flush mounting (as shown in the diagram above), use the screw bases and screws provided in the accessory package.

5. After completing the installation as described above, verify that the pointer is at the zero position to ensure accuracy. Use a flat head screwdriver to rotate the "zero adjustment screw" until the pointer rests at the "0"mark.

Pressure Connection:

• Positive Pressure/High Pressure (HIGH): Select either the bottom or side connection port. Use the pipe plug provided in the accessory package to seal the unused positive pressure port, Connect the pressure source to the selected port via the brass barbed hose fitting, and leave the negative pressure port open to the atmosphere.

• Negative Pressure/Low Pressure (Low): Select either the bottom or side connection port. Use the pipe plug provided in the accessory package to seal the unused negative pressure port. Connect the pressure source to the selected port via the brass barbed hose fitting, and leave the positive pressure port open to the atmosphere.

• Differential Pressure: Select either the bottom or side connection direction. Connect the higher pressure source to the High port and the lower pressure source to the LOW port using air hoses. Seal the unused ports with pipe plugs.

EN

EN

AR

AR

HR

HR

CS

CS

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ