Basic Selection Guide for Flowmeters: Customization Options for Specialized Industrial Needs

Flow meter series has become a preferred flow measurement device across industries like chemical engineering, petroleum, pharmaceuticals, environmental protection, food, and scientific research. It accurately measures single-phase, pulse-free fluids (liquids and gases), providing reliable data support for production and experiments in various sectors.

I. Diverse Model Options to Cover All Needs

LZB/LZJ Series: Includes standard and anti-corrosion (F Series) types, with port sizes 4-100mm. Suitable for scenarios like chemical engineering, papermaking, and sewage treatment; the anti-corrosion type resists corrosive media such as acids, alkalis, and oxidizers.

G/R/F Series: Available with three connection types (threaded, hose, flange), port sizes 15-50mm. It can replace imported production line equipment, ideal for light industry, pharmaceuticals, and environmental protection industries.

FA24 Series: Adopts advanced international technology, supports flange rotation alignment, port sizes 15-80mm. Combines high precision and easy installation, suitable for medium-to-large industrial scenarios.

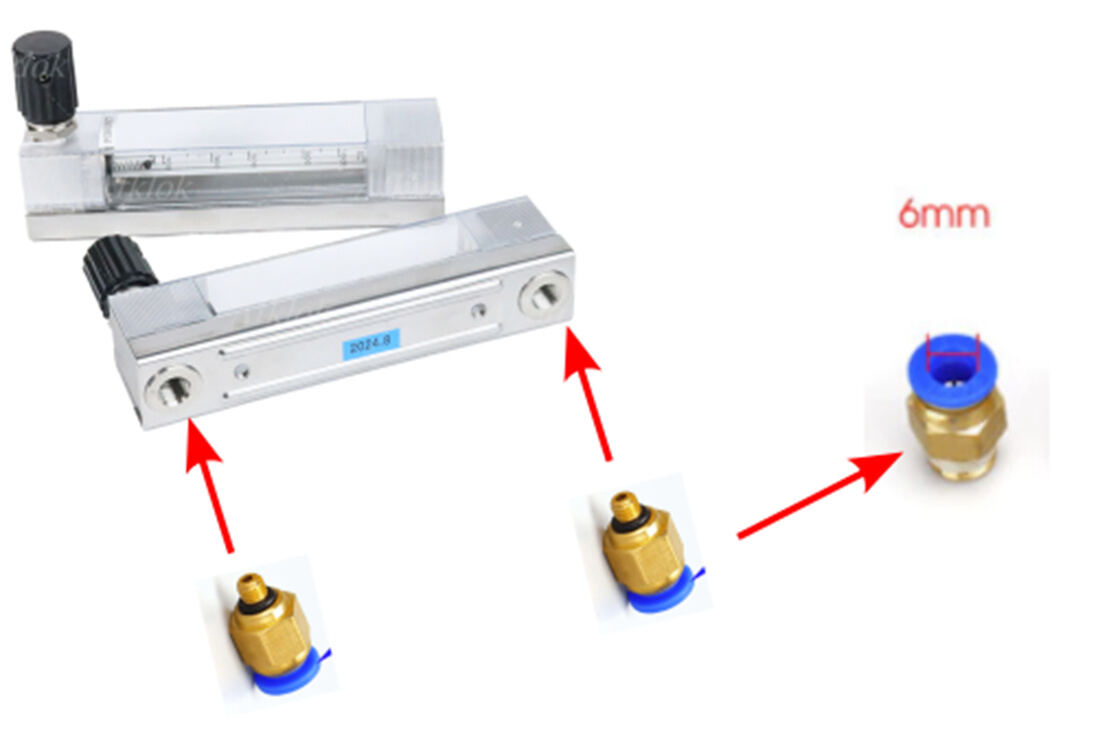

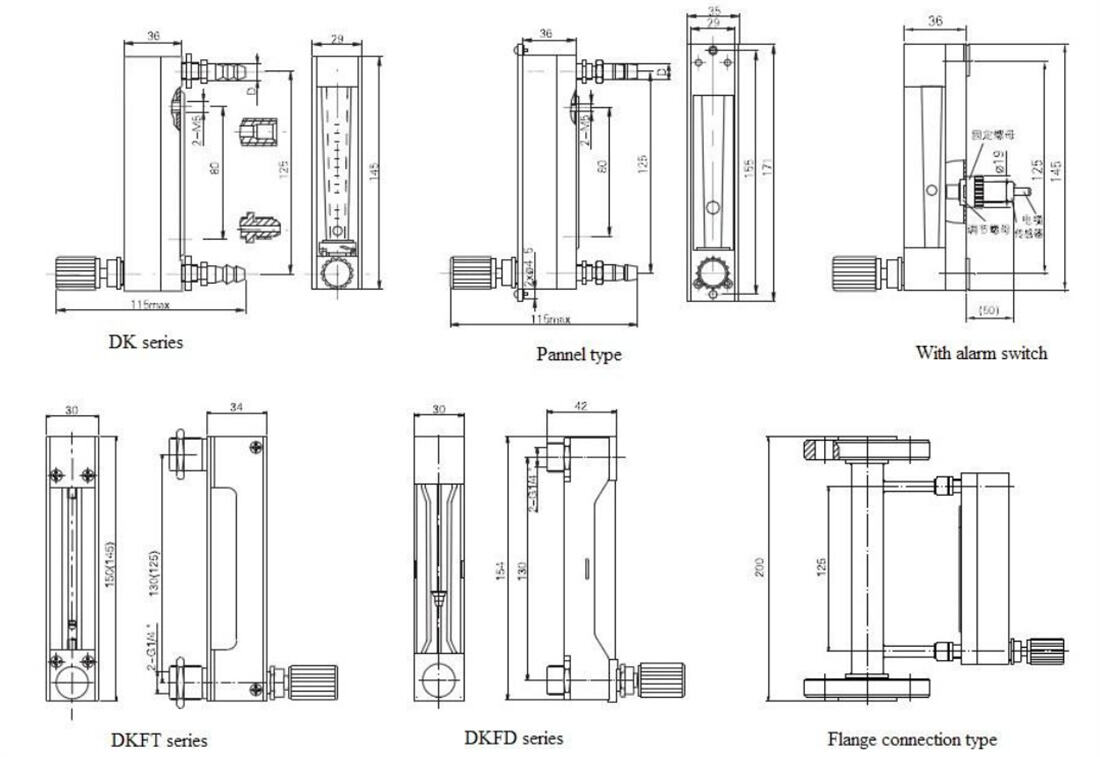

Micro-Flow Series (LZB-() W/WB, DK Series): Port sizes 3-10mm, with high measurement precision. Suitable for micro-flow scenarios like scientific research, medical care, and trace analysis.

Specialized Series: Includes all-stainless steel, all-PTFE, pull-rod anti-corrosion (LZB-TS), and split-flow (LZB-FL) types. Suitable for special working conditions such as high temperature, strong corrosion, and large flow.

II. Core Selection Parameters for Easy Matching

Choose a flow meter by clarifying 3 key parameters—no complex calculations needed:

Measured Medium: Specify the fluid (liquid/gas) and whether it is corrosive.

Specifications: Port size (3mm-300mm) and connection type (matching joints); flow range (working condition flow or standard condition flow).

Working Conditions: Operating pressure (max 6.4MPa), operating temperature (-20℃~200℃); whether explosion protection, signal output, etc., are required.

III. Key Advantages for Easy & Efficient Use

Strong Adaptability: Covers scenarios involving standard media, corrosive media, micro-flow, and large flow; custom materials (316L stainless steel, PTFE, etc.) are available.

Simple Operation: Clear, easy-to-read glass tubes; some models come with flow control valves, enabling quick use after installation.

Flexible Installation: Supports multiple connection methods (hose, threaded, flange) and mounting types (panel, wall-mounted).

Stable & Reliable: Measurement accuracy reaches Class 1.5-4; low pressure loss and long service life reduce maintenance costs.

IV. Flexible Connection Methods & Wide Flow Ranges for Different Scenarios

1. Flexible Connection Options

Small Ports (3-10mm): Hose connection, threaded connection (e.g., M10, G1/2").

Medium Ports (15-50mm): Threaded connection, flange connection (4-Φ14/18 mounting holes).

Large Ports (65-300mm): Flange connection (compatible with standards like ANSI, DIN, GB).

Special Connections: Custom options (quick connectors, ferrule connections, etc.).

2. Wide Flow Ranges for Precise Matching

Micro-Flow: 0.1ml/min-1L/min, suitable for scientific research, medical care, etc.

Standard Flow: 1L/h-10m³/h, suitable for daily production in chemical engineering, food, environmental protection, etc.

Large Flow: Up to 900m³/min, suitable for large industrial pipelines, water treatment, etc.

EN

EN

AR

AR

HR

HR

CS

CS

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ