Accurate Measurement, Choosing the Right Instrument: Analysis of Diaphragm Pressure Gauge Models, Structure, and Materials

In industrial production and experimental environments, diaphragm pressure gauges have become the preferred instrument for measuring corrosive, high-viscosity, or easily crystallizing media due to their special structural design. This article will comprehensively analyze the model classification, structural features, and material selection points of diaphragm pressure gauges to help you choose the most suitable product.

Analysis of Common Models of Diaphragm Pressure Gauges

1. Classified by connection method

· Radial type: The meter head and process connection are at a 90-degree angle, suitable for installation environments with limited space.

· Axial type: The meter head and process connection are coaxial, making it easy to read from the front.

· Flange type: With flange connection, suitable for high-pressure or special media applications

2. Classified by Functional Characteristics

· Standard Type: Basic measurement functions

· Shock-resistant type: Built-in damping fluid, suitable for vibrating environments

· Hygienic type: Complies with GMP standards, used in the food and pharmaceutical industries

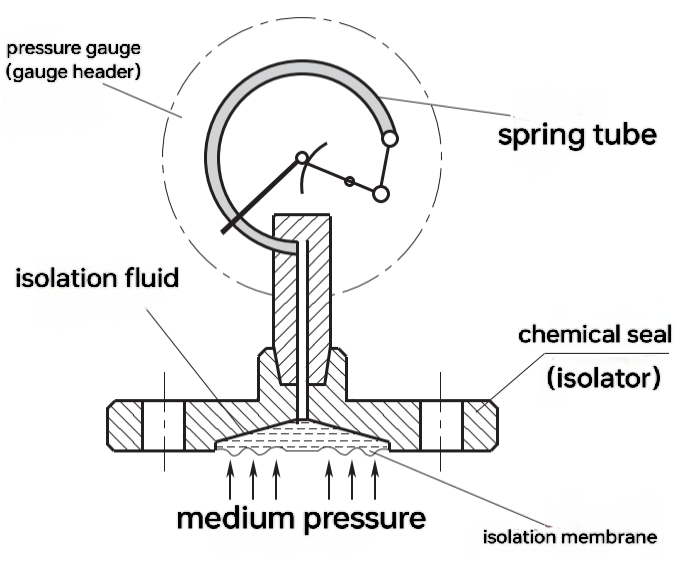

Analysis of the Core Structure

1. Diaphragm Isolation System

· Direct diaphragm: The diaphragm directly drives the movement, with a simple structure

· Indirect diaphragm: Pressure is transmitted through a filling fluid, providing more accurate measurements

2. Key Components

· Diaphragm sheet: The primary barrier in contact with the medium

· Filling liquid: different options such as silicone oil, glycerin, etc.

· Connector: The bridge between the process interface and the header

· Meter movement: Wave tube or diaphragm-type sensing mechanism

3. Special structural design

· Open flange: Easy to clean, suitable for viscous media

· With flushing ring: Can clean the diaphragm surface online

· Heat sink design: Suitable for high-temperature media

A Comprehensive Guide to Material Selection

1. Diaphragm material

· 316L Stainless Steel: A general-purpose choice, resistant to common corrosion

· Hastelloy C276: Resistant to strong acid and alkali corrosion

· Tantalum metal: Extremely corrosion-resistant, used in extreme environments

· PTEF coating: Anti-adhesive, suitable for media prone to crystallization

· Titanium alloy: Resistant to seawater corrosion, the preferred choice for marine engineering

2. Material of the parts in contact with the liquid

· 304 Stainless Steel: Economical Choice

· 316 stainless steel: Enhanced corrosion resistance

· Monel alloy: Resistant to hydrofluoric acid corrosion

· Polypropylene: Economical and Corrosion-Resistant Choice

3. Sealing Material

· Fluororubber (FKM): High temperature and oil resistant

· PTEF: Ultra-strong corrosion resistance

· EPDM: Excellent acid and alkali resistance

The Golden Rules of Selection

1. Priority on medium characteristics: First consider the causticity, viscosity, and temperature of the medium.

2. Pressure range matching: The working pressure should be within 1/3 to 2/3 of the measurement range.

3. Consideration of environmental factors: vibration, temperature, explosion-proof requirements, etc.

4. Compliance with Industry Standards: The food and pharmaceutical industries must meet specific standards.

5. Maintenance convenience: Consider the ease of cleaning and calibration.

Typical Application Cases

1. Chemical industry: Tantalum diaphragm used for measuring concentrated sulfuric acid

2. Food processing: 316L stainless steel + open flange

3. Pharmaceutical Industry: Sanitary Connection + PTFE Diaphragm

4. Marine Engineering: Titanium alloy material resists seawater corrosion

5. High-temperature oil products: Designed with heat sinks and high-temperature resistant filling fluid

Summary

Choosing the appropriate diaphragm pressure gauge requires a comprehensive consideration of the medium characteristics, working environment, and usage requirements. It is recommended to consult with professional technicians in detail before purchasing and provide accurate operating parameters to ensure the long-term stable operation of the instrument. Although high-quality diaphragm meters have a higher initial investment, they can significantly reduce maintenance costs and downtime risks, making them a more economical choice in the long run.

EN

EN

AR

AR

HR

HR

CS

CS

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ