Сборник планов технического обслуживания газового тракта

Обнаружение и устранение утечек газового тракта (недорогое решение)

A. Метод обнаружения утечек с помощью мыльной воды: нанесите мыльную воду на соединения труб, клапаны и другие потенциальные места утечек и наблюдайте за образованием пузырей, чтобы определить место утечки. Затем затяните или замените уплотнительные детали.

B. Испытание на удержание давления: после закрытия газового источника понаблюдайте за манометром. Если давление продолжает падать, значит, есть утечка. Необходимо проверить участки по отдельности.

C. Недорогие уплотнительные материалы: используйте тефлоновую ленту или уплотнительные кольца из силиконовой резины вместо дорогих специальных уплотнительных деталей, подходящих для газовых магистралей низкого давления.

Оптимизируйте прокладку газового тракта, чтобы уменьшить потери давления

A. Укоротите путь газового потока: минимизируйте ненужные колена и длинные трубопроводы, чтобы снизить сопротивление воздушному потоку.

B. Сократите количество прямых углов в трубопроводах: замените их на колена с большим радиусом изгиба или гибкие шланги, чтобы уменьшить потери давления из-за турбулентности.

C. Оптимизируйте согласование диаметров труб: избегайте слишком узких труб, создающих узкие места, обеспечьте беспрепятственное движение воздушного потока.

Интеллектуальный недорогой мониторинг

A. Недорогие датчики давления + цифровые дисплеи: осуществляйте постоянный контроль давления в газовом тракте для своевременного выявления отклонений.

B. Функция мобильных уведомлений: подключите датчики давления через модули Wi-Fi для отправки сигналов тревоги при возникновении аномалий.

Оптимизация обслуживания и управления

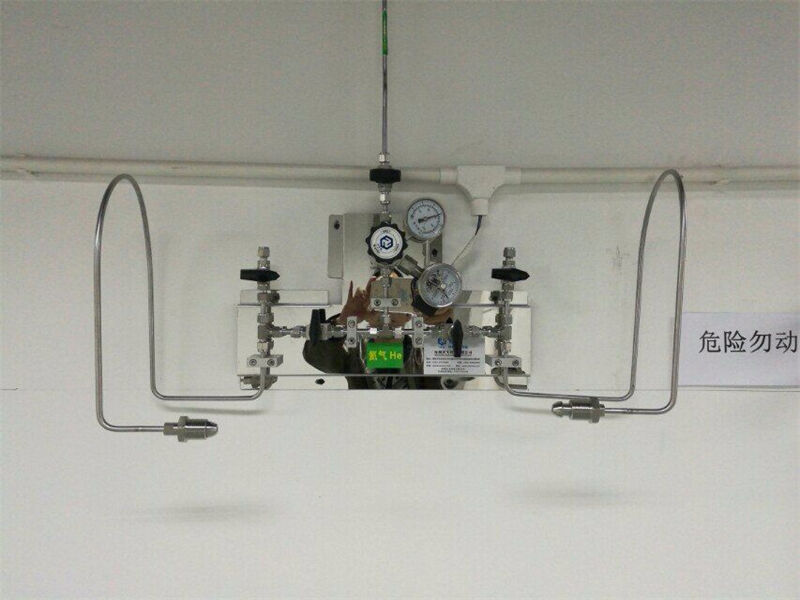

A. Чек-лист регулярного технического осмотра: разработайте простой график технического обслуживания для периодической проверки ключевых компонентов, таких как соединители, фильтры и манометры.

B. Обучение персонала: повышайте осведомленность операторов о необходимости обслуживания газового тракта посредством внутренних тренингов, чтобы сократить ошибки, вызванные человеческим фактором.

EN

EN

AR

AR

HR

HR

CS

CS

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ