The “Delivery Code” for Semiconductor “Food”

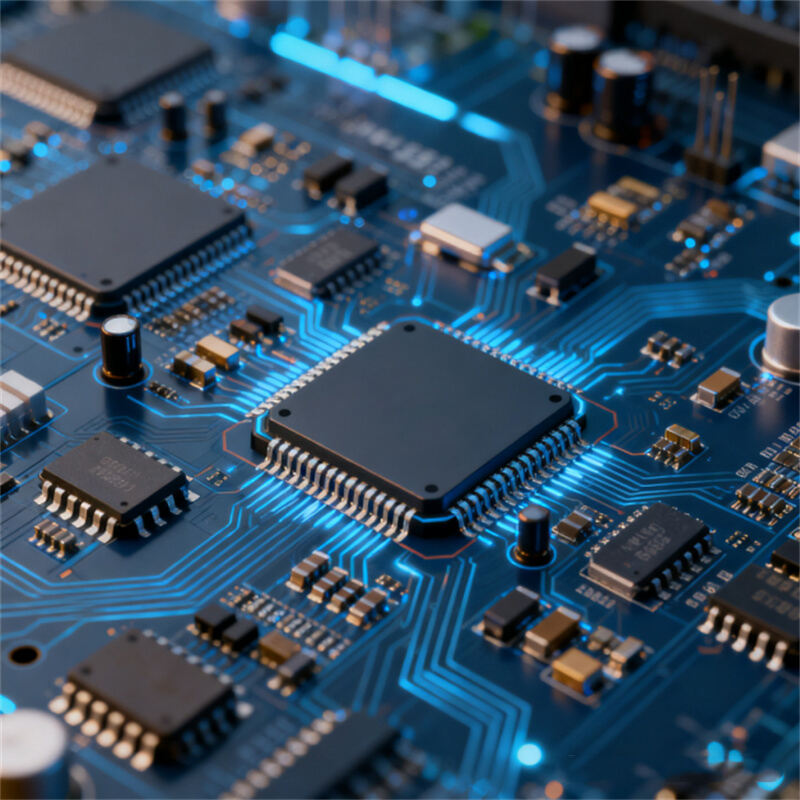

From overcoming critical bottlenecks to accelerating domestic substitution, China's semiconductor industry is undergoing profound transformation. While attention often centers on star equipment like lithography and etching machines, a crucial yet overlooked link in the supply chain remains: electronic specialty gases and their delivery systems.

As the “invisible cornerstone” of chip manufacturing, the purity and delivery stability of electronic specialty gases directly determine chip yield and performance, making them a critical factor in safeguarding the entire semiconductor industry ecosystem.

At the Bay Area Semiconductor Industry Ecosystem Expo, which brings together forces from across the supply chain, Wofly Technology will showcase its core products. Visitors will gain firsthand insight into breakthroughs in precision, safety, and adaptability, helping build bridges for technical exchange and collaboration!

The “Invisible Barriers” in the Semiconductor Industry

Amid the relentless push for domestic substitution in the semiconductor industry, while countless eyes fixate on breakthroughs in “national heavyweights” like lithography machines and etchers, a hidden lifeline deep within the supply chain—electronic specialty gases and their delivery systems—is quietly determining the success or failure of the industry's breakthrough. If chips are the “heart” of the digital age, then electronic specialty gases are the ‘blood’ that keeps that heart beating. The delivery systems form the “vascular network” that circulates this blood. Any blockage or leak within this network could bring an entire wafer production line to a standstill.

China's semiconductor industry has long faced dual constraints on its “blood” and “blood vessels”: domestic production of high-end electronic specialty gases remains below 20%, with critical varieties reliant on imports at persistently high prices. Moreover, the precision and safety of transmission systems struggle to meet the demands of advanced manufacturing processes.

As domestic substitution evolves from “breaking through scarcity” to “pursuing stability,” Wofly Technology has taken the lead in shouldering the responsibility of “vascular engineers.” We understand that safeguarding the semiconductor industry's “breathing lifeline” requires not only overcoming technical barriers but also building solutions compatible with the domestic ecosystem. Every technological innovation targets the industry's most pressing pain points.

Wofly Technology's transmission systems ensure the purity and unimpeded flow of this “blood” with millimeter-level precision. We are accelerating the formation of a domestic closed-loop system for “special gas production - transmission - application,” enabling the semiconductor industry's ‘breathing’ to become more autonomous and robust, and injecting “precision engineering strength” into the battle for domestic substitution.

The Key to Ecological Breakthrough

The healthy development of the semiconductor industry requires coordinated breakthroughs in materials, equipment, and transmission systems. Compared to gas synthesis, the precision and safety of specialty gas transmission are often overlooked, yet they represent the “last mile” that determines the effectiveness of the gases.

1. The Transmission Revolution: From “Having” to “Having the Best”

The core battleground for domestic substitution has shifted from “whether production is possible” to “whether stable supply is achievable.” It is estimated that by 2026, the domestic substitution rate for electronic specialty gases must exceed 40%. This not only demands quality upgrades for the gases themselves but also requires technological support for the delivery systems—after all, even the finest ‘grain’ requires reliable “pipelines” to deliver its value.

2.Strengthening the Foundation for Stability in the Semiconductor Industry Chain

With the nation's increasing support for the semiconductor industry, the wave of domestic substitution is advancing at an unprecedented pace. From technological breakthroughs in “national heavyweights” like lithography machines and etching equipment to the independent R&D of core materials such as electronic specialty gases, each step contributes to enhancing the autonomy and controllability of the industrial chain.

Through customized, high-precision specialty gas delivery solutions, we proactively shoulder the responsibility of being a “chain stabilizer” in the industrial chain. With solid technology and service, we make the semiconductor supply chain more stable.

Fortify the transmission security defense line

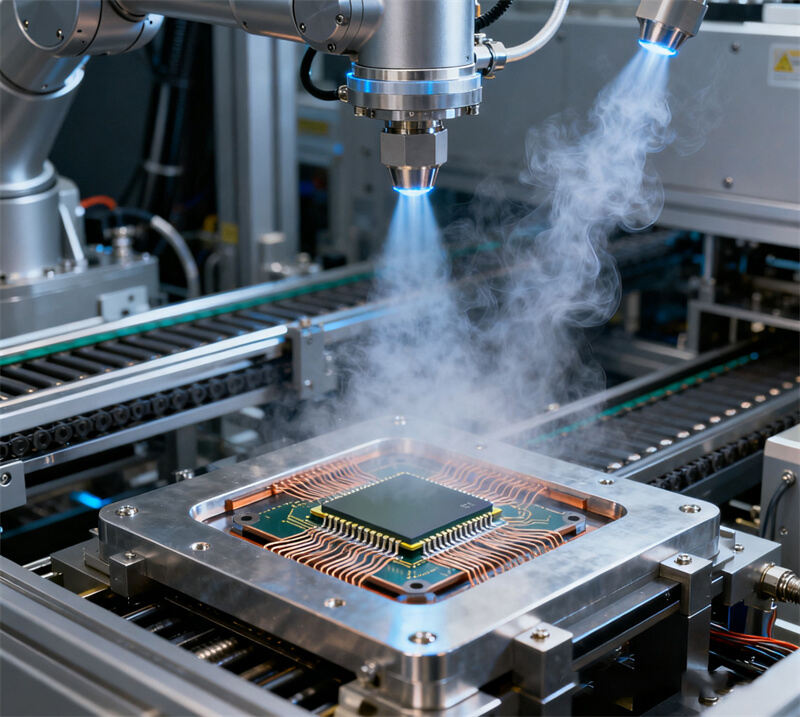

After gradually reducing reliance on imported specialty gases, ensuring their safe and stable transportation has become the key to breaking through challenges in the industrial chain. With over a decade of expertise in high-purity fluid systems, Wofly Technology centers its approach on precision engineering to deliver comprehensive solutions covering purity, safety, and compatibility, thereby fortifying the security of specialty gas transportation.

1. Precision Answer

Safety protection is another core pillar of Wofly's precision engineering solutions. In the handling of electronic specialty gases—which include highly toxic, flammable, and highly corrosive substances—any oversight in the transmission system could trigger safety incidents or even halt production lines.

2. Controllable and preventable

Our proprietary products effectively counteract expansion losses caused by long-term gas transmission while preventing external impurities from infiltrating. Paired with a real-time leak monitoring system, they trigger alarms and shut off pathways within 0.5 seconds upon detecting abnormal gas concentrations. This creates a triple-layered safety barrier of “prevention-monitoring-emergency response,” ensuring hazardous specialty gas transmission remains fully “controllable and preventable” throughout the entire process.

3. Safety Protection

We consistently align with the domestic industrial chain, fortifying the ecological security barrier through customized adaptation. For diverse product characteristics, we tailor transmission system parameters—including pressure settings, material selection, and interface design—to facilitate seamless integration across the domestic closed-loop process of “special gas production, transmission, and application.” Simultaneously, we provide compatible solutions for related fields such as centralized laboratory gas supply and biopharmaceutical manufacturing. This enables our precision engineering to extend across multiple industrial segments, delivering comprehensive safety protection across diverse scenarios and the entire supply chain.

Eco-Prosperity / Safeguarding the Semiconductor Industry's Autonomy and Control

For a decade, Wofly Technology has steadfastly adhered to the ecological principle of “collaborative symbiosis”—never defining ourselves as mere equipment suppliers. Instead, we serve as “end-to-end partners,” tailoring integrated solutions that deliver “purity assurance + safety control + cost optimization,” ensuring every technical detail precisely aligns with industrial demands.

We remain anchored in technological innovation, continuously deepening our expertise in the R&D of high-purity fluid systems. We firmly believe that every meticulously crafted transfer device serves as an indispensable “robust blood vessel” within the semiconductor ecosystem: it embodies the extreme precision demands of advanced processes, safeguards the safety baseline of production lines, and drives industry cost reduction and efficiency gains through its high cost-performance advantage.

Wofly Technology—the “lifeline” safeguarding the chip industry. Using exhibitions as a window, we empower the shared prosperity of the Greater Bay Area's semiconductor ecosystem!

EN

EN

AR

AR

HR

HR

CS

CS

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ