Wofly Specialty Gas Cabinet: Building a "Safe and Efficient Shield" for the Mass Production of Silicon-Anode Solid-State Batteries

Amid the wave of new energy battery technology iteration, silicon-anode solid-state batteries, with their energy density far exceeding that of traditional batteries, have become a core direction to solve the range anxiety issue. However, from laboratory breakthroughs to large-scale production, the safe control and precise supply of specialty gases have always been a major "obstacle" that the industry urgently needs to overcome. The independently developed specialty gas cabinet by Shenzhen Wofly Technology Co., Ltd., with its professional gas control capabilities, is clearing the hurdles for the mass production of silicon-anode solid-state batteries and serving as a key support for the practical application of this technology.

The performance leap of silicon-anode solid-state batteries is inseparable from the "technological empowerment" of specialty gases. Silane gas, as a core raw material for the preparation of silicon-carbon anodes, forms a conductive carbon layer on the surface of silicon particles through a chemical vapor deposition process, which is crucial for improving the cycle stability of batteries. Acetylene gas can form a protective film on the material surface through coating technology, effectively alleviating the volume expansion problem of silicon anodes during the charge-discharge process. Inert gases such as nitrogen provide a protective atmosphere for the production process, ensuring the stable performance of materials. Nevertheless, most of these gases possess flammable, highly toxic, and corrosive properties. Silane can ignite spontaneously upon contact with air, and sulfide gases tend to form toxic substances when in contact with water vapor, posing severe challenges to production safety.

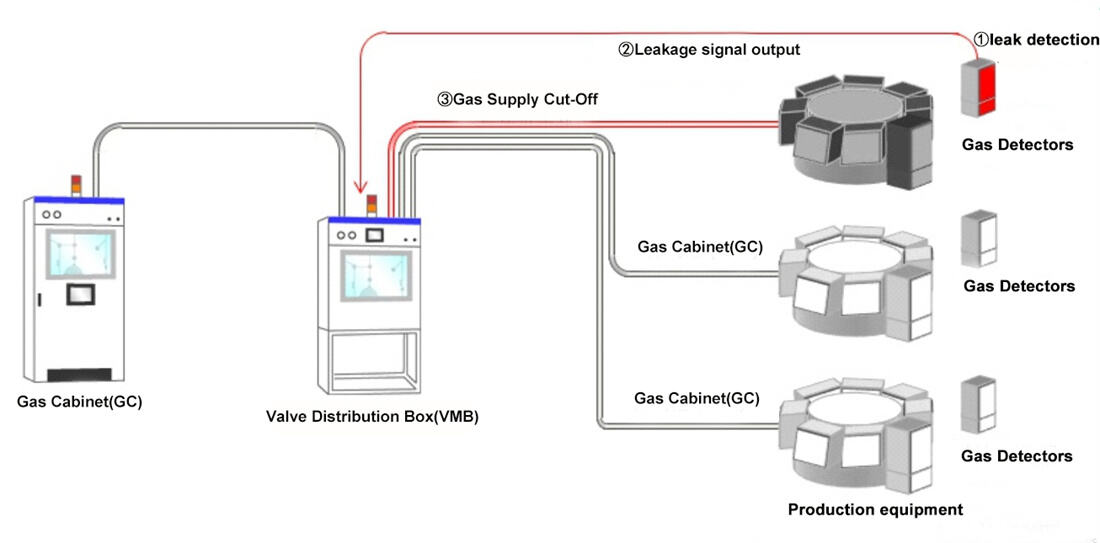

Through comprehensive safety design, Wofly Technology's specialty gas cabinet has built the "first line of defense" at the production site. The cabinet body is made of high-strength corrosion-resistant plates, and combined with explosion-proof observation windows, it enables visual monitoring of the safety status. A negative pressure environment is maintained inside the cabinet at all times, preventing the diffusion of leaked gases from the source. Special sealing technology is adopted for the core connection parts to minimize the risk of gas leakage. Even in the event of a trace leak, the built-in high-precision monitoring system can detect it instantly and immediately trigger chain reactions such as automatic gas supply cutoff and emergency purging, providing multiple guarantees for production safety. To meet the processing needs of special gases like sulfides, the equipment is also integrated with a dedicated exhaust gas treatment module. Through multiple processes including decomposition and adsorption, it ensures that emissions comply with environmental protection standard.

In terms of process adaptability, Wofly's specialty gas cabinet achieves "precision supply" of specialty gases. Different stages of silicon-anode production have strict requirements for gas flow rate and concentration. The equipment, equipped with customized valve groups and an intelligent control system, can automatically adjust the gas supply status according to process parameters, ensuring the stability of key processes such as carbon layer deposition. Considering that multiple types of gases need to be used simultaneously in production, the specialty gas cabinet is designed with a multi-gas path integrated structure, which can flexibly switch gas supply modes to adapt to the needs of complex processes like plasma-enhanced chemical vapor deposition,avoiding efficiency losses caused by frequent equipment replacement. Meanwhile, the ultra-high-purity gas delivery environment created by the equipment effectively reduces the impact of impurities on battery performance, laying a solid foundation for improving product quality.

Wofly's specialty gas cabinet brings dual improvements in safety and efficiency. In terms of safety management, the equipment has obtained multiple international safety certifications such as ATEX and CE. Its comprehensive leak detection and emergency response system significantly reduces the risk of using specialty gases and eases the pressure of enterprise safety management. In terms of production efficiency, the integrated gas control solution reduces losses in equipment connection links. Combined with the intelligent gas recovery function, it significantly improves the utilization rate of raw materials and helps enterprises control production costs. In this new energy technology revolution, Wofly's specialty gas cabinets, with their core advantages of safety, precision, and efficiency, are injecting strong momentum into the acceleration of solid-state battery mass production and helping the new energy industry move towards a higher-quality development stage.

EN

EN

AR

AR

HR

HR

CS

CS

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

AZ

AZ