Gas, when we think of it, is often of the variety used to fuel our cars or to cook our food. But did you know there are many different types of gas? Every sort of gas is suitable for unique tasks. Nitrogen gas is one of the most important gases used by industries or factories. This gas is used in many processes, and it is highly valuable in many industries.

Nitrogen gas is a special type of gas that is used in factories because it does not create a reaction. Thus, it can be used safely in environments where chemical reactions would be hazardous. For instance, there could be unwanted reactions that could harm people or damage equipment when chemicals are mixed. One more thing, managing the pressure of the nitrogen is crucial to preserving everything secure. The pressure has to be correct, too high and it's dangerous, too low, and the work will not be done correctly.

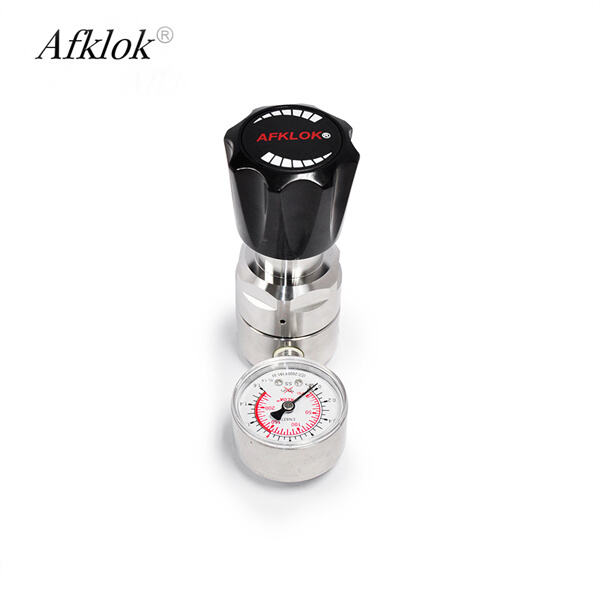

Nitrogen gas pressure regulator is a purpose-made equipment used for the pressure regulating of nitrogen gas. It accomplishes this by extracting high-pressure gas from a tank and dropping it to an appropriate low pressure and flow rate for the required application. This is very important because high pressures can break machines, or worse, cause explosions, which can be very dangerous. If the pressure is too low on the other hand though, it can cause the process to run slowly or even be made to stop altogether.

When it comes to keeping workers and factories safe, nitrogen gas pressure regulators are key. They record it only up to October 2023. Such as high pressure of nitrogen gas can cause equipment failure or explosion. Such accidents can result in danger for workers. On the other hand, an excessively low pressure can slow down the entire production process or render it infeasible.

A nitrogen gas pressure regulator. This is used to keep the pressure at a safe and stable level. This is done to prevent accidents and make sure everything runs smoothly. The bottom line is when it is working the right way the work can go on efficiently and safely and it is good for all parties involved.

Nitrogen gas pressure regulator also gives you a very fine control over the pressure of the gas. This is especially important for work in which the right amount of pressure needs to be applied to achieve the optimal outcome. In the food packaging industry, for example, nitrogen gas is regularly used to preserve food freshness. But the pressure has to be just right so the packages seal properly. If pressure is not sufficient, for example, packages may fail to seal properly resulting in spoilage or other issues.

No nitrogen gas pressure regulator would make it much more difficult to achieve this perfect pressure. A regulator keeps the pressure at a constant level, so that the quality of the products being processed remains consistent. Such accuracy is crucial in many industrial operations to produce items that meet safety and quality standards.

Shenzhen Wofly has invested in ongoing research and development to ensure that they are able to stay at the top in this field. The company is able introduce new technologies and products to nitrogen gas pressure regulator the evolving requirements of the market as well as advances in gas supply systems.

Shenzhen Wofly puts customer satisfaction first and offers responsive, personalized service throughout the entire lifecycle. The company offers complete gas supply solutions that include consultation on design and nitrogen gas pressure regulator, installation, maintenance and testing. It is also able to improve its products and services by taking into account feedback from customers.

Shenzhen Wofly provides a nitrogen gas pressure regulator solution to all your gas supply needs. From design and consultation, through production, installation, test, and maintenance. We are able to ease the burden having to deal with multiple suppliers by streamlining our clients' processes. We can provide tailored efficient solutions that are able to satisfy the requirements of every customer. We keep abreast of the latest developments and trends in the industry and are able to offer the most innovative solutions.

Shenzhen Wofly's expertise in the industry and expertise in technology permits them to design and produce high-purity gas supply systems as well as the related components, that are specifically nitrogen gas pressure regulator to industrial needs. The company understands that each industry faces unique challenges and constraints. They can meet these challenges with customized solutions, and ensuring optimal performance.